Solutions by Industry

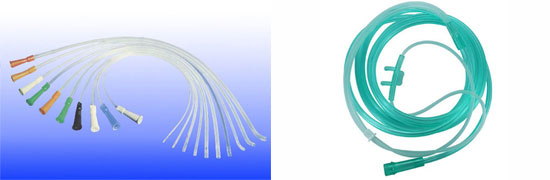

Extrusion Tubing

We produce mainly medical tubes using profile extrusion. We are capable of working with a broad range of materials including PVC, PS, PP, PE and PETG.

In the profile extrusion process, raw material in pellet form is loaded into the extruder for kneading and melting before it is extruded through a heated die which forms the molten plastic into the required shape and dimension. The solidified tube is slowly pulled out through the cooling tanks by a pulling device for a subsequent cutting process which cuts the tubes into pre-determined lengths.

Return to Solutions by Industry page.