Solutions by Industry

Precision Injection Moulding

In the precision injection moulding process, the raw material is pre-loaded into a material bin. An autoloader feeds the raw material (pellet or granule form) into the injection machine hopper. The raw material is melted in the barrel of the machine and injected under high pressure into the mould. The molten polymer is allowed to cool and solidify, and removed from the moulds. If needed, the parts are cleaned with de-ionised water and dried with hot air blowers. They are then inspected before packed for delivery.

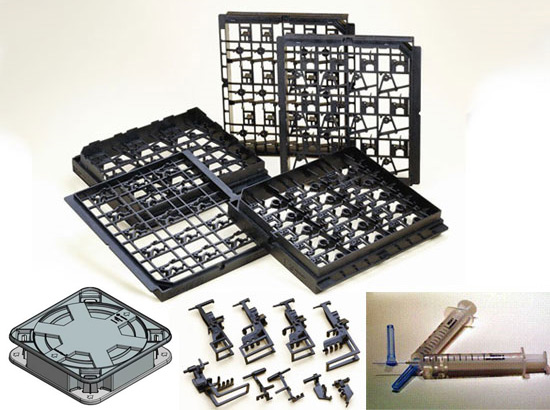

IC trays, wafer shippers, HDD trays, shipping combs and hoods, medical components and devices as well as other high-precision plastic parts produced using precision injection moulding are used in the semiconductor, data storage and consumer electronics, medical and automotive industries.

With fully automated precision injection moulding machines of various tonnages (from 40 to 450 tonnage), our moulded products meet stringent dimensional, functional and aesthetic requirements of customers. We also offer clean room facilities for molding medical products, as well as washing and packing various products, if contamination-free moulded parts are required.

Return to Solutions by Industry page.